Welcome to the September issue of Materials World

'I think of myself as a microscopist trying to solve problems, rather than somebody who’s trying to develop a better microscope for the microscope’s sake,' reflects Sarah Haigh. Our reporter, Alex Brinded, catches up with the materials scientist at the University of Manchester, UK, as she steers a project to add artificial intelligence and automation capabilities to transmission electron microscopy.

Her comments sum up the premise of this issue as our contributors outline an almost forensic, detective-like approach to solve ‘problems’ in different disciplines using various testing, inspection, sensing and metrology solutions.

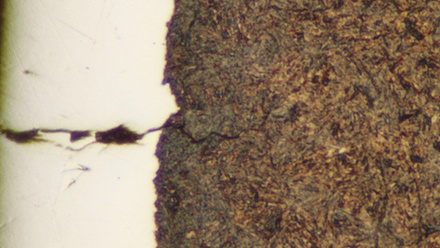

Authors from Minton, Treharne & Davies assert that 'failure analysis demands that the right questions are asked to determine the root cause', as they navigate a series of case studies.

Indeed, in his article on failure analysis on big yellow machines in the construction industry, Jason Webb MIMMM adds, 'The main aim of a failure investigation is to determine the root cause of the failure. This should not be confused with the root cause of fracture.

'Several days or weeks spent on a failure investigation to determine the failure mode may draw the celebrations and high-fives from the metallurgists in the office, but it will not help the customer-facing engineer who needs to understand what has caused the part to fail.'

Whereas the team at the UK’s National Physical Laboratory are on a mission to champion the role of metrology in the race to net-zero.

We hope you enjoy this issue.

Rupal Mehta, Editor